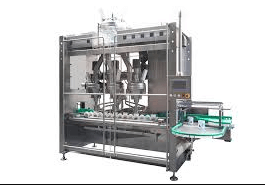

What are the Different Types of Filling Machines?

In the world of manufacturing and production, filling machines play a pivotal role in ensuring that products are efficiently packaged and ready for distribution. These machines come in various types, each designed to handle specific products and production requirements. In this comprehensive guide, we’ll delve into the different types of filling machines, exploring their functionalities, benefits, and applications.

Introduction

Dog Food Filling Machines are essential components in the production and packaging process across various industries. They automate the process of transferring products into containers, ensuring accuracy and efficiency while minimizing wastage. Different types of filling machines are available to accommodate a wide range of products, from liquids to powders and even viscous substances.

Gravity Filling Machines

Gravity-filling machines, also known as overflow fillers, rely on the principle of gravitational force to fill containers. These machines are ideal for free-flowing liquids and work by filling the container to a predetermined level, ensuring consistent fill volumes.

Piston Filling Machines

Piston-filling machines use a piston and cylinder mechanism to accurately measure and dispense products. The piston draws in the product and then pushes it into the container, making it suitable for both thin and thick substances.

Volumetric Cup Filling Machines

Volumetric cup-filling machines employ a series of cups that measure a specific volume of the product before dispensing it into containers. These machines are commonly used for granular and small-particle products.

Auger Filling Machines

Auger filling machines are designed for powdery or granular products. They use a rotating auger screw to dispense a predetermined amount of product into containers, ensuring precision and minimizing dust.

Net Weight Filling Machines

Net weight filling machines are used to fill products based on their weight. The container is weighed before and during filling, and the machine adjusts the fill volume to achieve the desired weight.

Time-Pressure Filling Machines

Time-pressure filling machines operate by filling containers within a specific time frame and under pressure. This method is suitable for foamy or carbonated products that require careful handling.

Overflow Filling Machines

Overflow filling machines are commonly used for filling liquids into containers with consistent fill levels. The excess product overflows back into the supply tank, ensuring accurate fill volumes.

Peristaltic Filling Machines

Peristaltic filling machines utilize a rotating roller mechanism to compress a flexible tube and dispense the product. These machines are ideal for sterile and precise filling, making them suitable for pharmaceutical and food industries.

Aseptic Filling Machines

Aseptic filling machines maintain a sterile environment during the filling process, ensuring that the product remains uncontaminated. They are vital for industries requiring high hygiene standards.

Liquid Filling vs. Powder Filling

The choice between liquid and powder filling depends on the nature of the product. Liquid-filling machines are suitable for beverages, oils, and other liquids, while powder-filling machines are designed for dry products like spices, flour, and pharmaceutical powders.

Choosing the Right Filling Machine

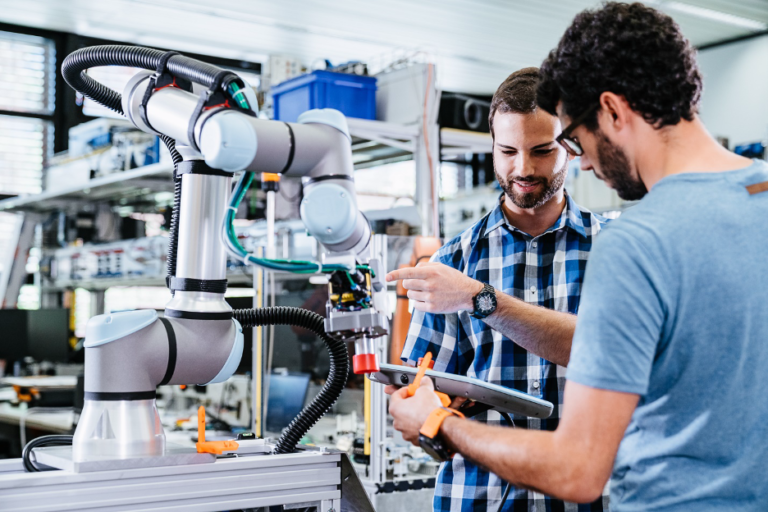

Selecting the appropriate filling machine requires considering factors such as product viscosity, container size, fill volume, and production speed. Manufacturers need to choose a machine that aligns with their specific requirements.

Factors to Consider

When investing in a filling machine, manufacturers should consider factors like cost, maintenance, operator training, and compatibility with existing production lines.

Maintenance and Care

Regular maintenance and proper care are crucial for the longevity and performance of filling machines. Routine inspections, cleaning, and prompt repairs contribute to seamless operations.

Conclusion

Dog Food Filling Machinesare indispensable tools that streamline the packaging process across diverse industries. From gravity and piston fillers to aseptic and peristaltic machines, each type has its unique advantages. Manufacturers must carefully assess their product and production needs to make informed decisions when choosing the right filling machine.

FAQs

- Q: How do gravity-filling machines work? A: Gravity-filling machines operate by allowing the product to flow into containers based on gravitational force.

- Q: What products are best suited for piston-filling machines? A: Piston filling machines are versatile and can handle both thin liquids and thick substances like sauces and creams.

- Q: Are volumetric cup-filling machines suitable for large particles? A: Volumetric cup-filling machines are more suitable for small-particle products like grains or seeds.

- Q: What are the advantages of using aseptic filling machines? A: Aseptic filling machines ensure product sterility, making them essential for industries with strict hygiene requirements.

- Q: Can I use the same filling machine for both liquids and powders? A: It’s recommended to use different machines for liquids and powders to achieve optimal filling precision and efficiency.